Product Description

Precast Concrete Magnet is suitable for all kinds of formwork construction as steel and plywood shuttering system with appropriate adaptor, are composed with very strong permanent magnets ( neodymium magnet) and a shielding steel box. The workers could push or pull the above button to make the magnetic box performed adhesive force or not with a steel sticker.It's very easy to control according to requirements.As a professional magnetic assemblies designer and manufacturer, we, Shine Magnetics, have helped and designed many types of precast concrete magnets for our customers from all over the world, such as 900kgs U shape shuttering magnets, 1350kgs shuttering magnet, 1600kgs magnet box, 2100kgs magnetic formwork system, 3100kgs precast concrete magnet.

Advantages of using precast concrete magnet

- Workers could quickly build concrete formwork according to individual architectural design.

- Workers could contemporaneously build different concrete formworks in one time.

- Even during the building process,workers could adjust the concrete formwork.

- significantly save time that cost on installation of magnetic formwork.

- No need electric welding, which requires high energy consumption.

- Reduce damage to the concrete platform in the working.

Important informations

1. The magnet is enormously strong and leave hands under the magnets will cause serious danger.

2. Please Do not use precast concrete magnet directly on the concrete.

3. Find the suitable metal adapter to fix the hex nut.

Advantages

1 All NdFeB magnets used are made by our own magnet factory.

2 Standard producing process and strict quality checking

3 Competitive price, stable quality, in time response

4 Trained working staff

Delivery & Packing:

Popular Model: 5-10 days after receipt of payment

Customer Tailored Size: 15-20days

Packing: Plywood Box.

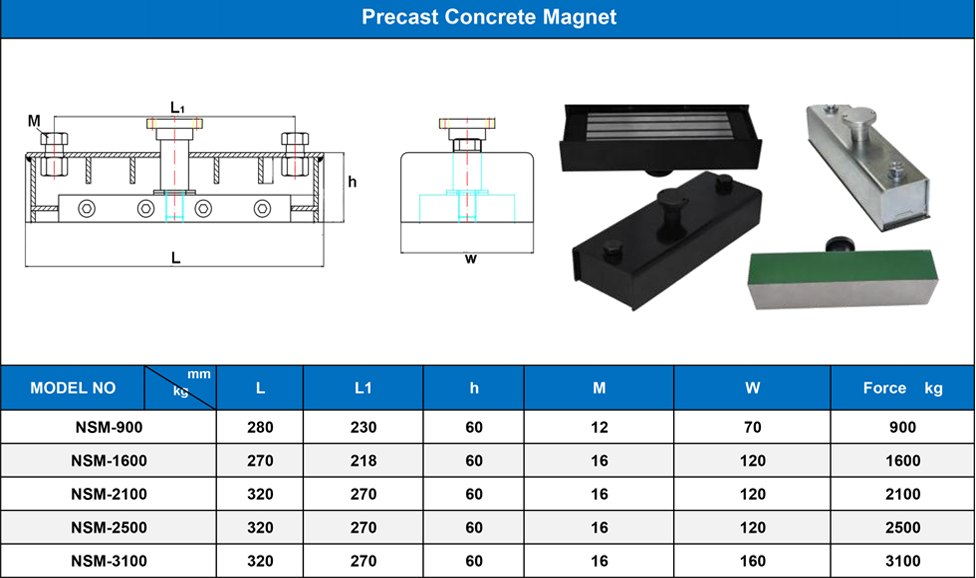

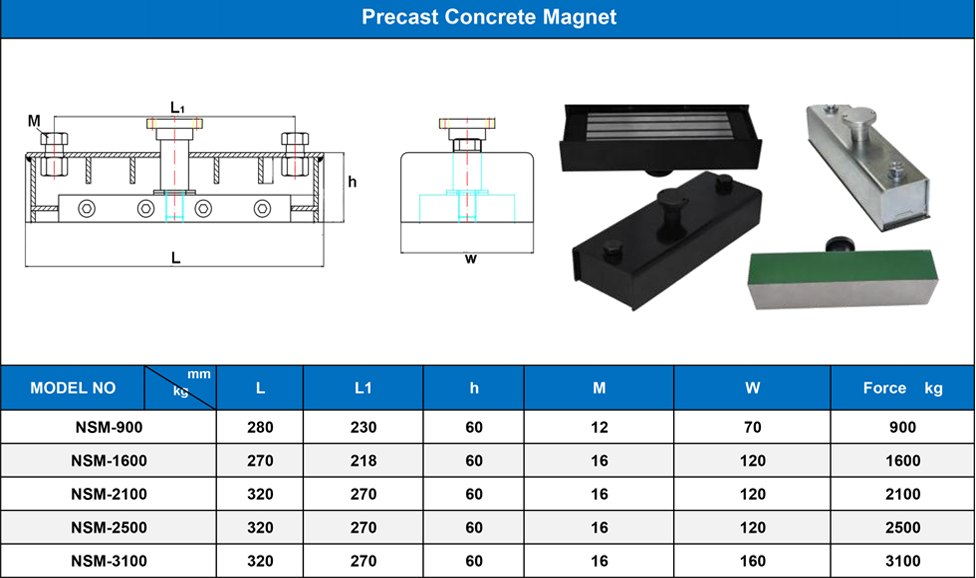

Detailed specifications:

1.Material: NdFeB magnets + Metal House (well surface treatment from corrosion)

2.Size: As per the table. Customer tailored design are available.

3.Coating: As Per customers requirement.

4.Certificates: ISO9001:2000,ROHS

Detailed FAQ:

1.What is the PC component template magnetic fixing device?What role does it play in the production of PC components?

The production of PC components is usually made of steel mold and precast concrete,the traditional fixed mold combination is used screw fixation,at this way, to spend a lot of time in the process of group mode and dismantling, artificial,there may be a need to punch holes on the platform, or even different component sizes in different locations,so this destroys the platform, shortens the service life, and may even affect the quality of the component,the use of high strength rare earth permanent magnet materials produced by magnetic fixing device can solve these problems.We fix the PC component template by magnetic force,Fixed device to replace the screw nut called PC magnetic component template fixing device.The magnetic fixing device is closely combined with the steel mould and the platform through the magnetic force and does not produce any damage to the die,And our magnetic device design of the switch system, by closing the magnetic force, can be quickly and easily remove the mold.

2.What is the advantage of your company's fixed die box? How long is the service life? What is the cost? What is the quality standard?

The quality of the fixed magnetic box is reliable and the technology is mature in Shine Magnetics.We can according to customer needs, design and production of different suction, different sizes of magnetic boxes,At the same time, according to the customer's different template specifications, size, the use of the environment, the design of the corresponding fixture system.Our advantage is also reflected in the timely delivery and thoughtful service.

We design a convenient switch system and a special switch(releasing tool) in supporting the crowbar, the switch is closed, the magnetic sealing performance, it is very safe and convenient.

Because the magnetic box is a permanent magnet, in the operating temperature range, in principle, is to maintain permanent magnetic force,At the same time, the design also takes into account the harsh environment of the construction site.However, as a kind of tool, the service life of the magnetic box is related to the usage, the use environment and the maintenance.

We are specialized in the production of magnet assembly plant, has the advantages of processing facilities and large-scale production, so our price is very competitive in the market.

We have a professional test equipment for magnetic box suction, to ensure that each product is in line with customer requirements for suction,At the same time, we require that the magnetic box in the closed state of the switch, the magnetic shielding effect is good, workers can easily remove the magnetic box from the platform.

3.What are your clients at home or abroad? What is the market share? What are the items currently being used in your company?

Our PC component template magnetic fixed device in 2010 on the bulk of exports to the Middle East, Southeast Asia and other countries, in overseas has a good reputation and visibility

In the domestic market, we have a lot of in-depth discussions with the component manufacturers, some of which have been used in batch production of components of our products, such as YUHUI, HaiLong, ZHONGTIAN.

4.How to choose the appropriate PC component template magnetic fixing device, what is a good suggestion?

(1):First of all, We think it is necessary to select the appropriate size of the magnetic box according to the different components.If the suction is insufficient, will cause the fixed template is not solid, affect the quality of components, it is The loss outweighs the gain.

(2):Secondly, the product is rust, sealing performance, maintenance is convenient, that is, product life.The magnetic box may cause the work of magnetic attenuation in the use process, this is because of the combination between the surface and the magnetic platform is not tight enough to work with concrete goods Other Waste accumulation in the magnetic surface, affecting tightly, attenuation caused by suction.At the same time, if there are concrete or other garbage into the magnetic box inside, or switch rust, affect the use of switches, may also cause the magnetic field can not be closely linked with the platform, and then magnetic attenuation.

(3):Finally, the product is safe to use, light, that is, when the switch is closed, the work of the magnetic force is significantly attenuated, whether it is easy to move the magnetic box.

Contact Now

Contact Now